This article will explain the reverse osmosis water filtration process and how it is used in soft water species aquariums, including angel fish and discus fish. RO water is also used to build water for marine and reef aquariums. A reverse osmosis filter is not used to filter water that is inside the aquarium. RO filters are not aquarium filters. RO filters are used to purify and soften tap water for use in filling aquariums and changing water. Soft water is necessary when lower ph values are required. Pure water is necessary for marine and reef aquaria. As you will see, this pure water must be “reconstituted “to make it suitable for aquarium inhabitants. Osmotic reverse osmosis filters are designed for the high output needs of aquarium use.

A Brief Look At Aquarium Filtration

The primary purpose of aquarium filtration is to remove harmful by products produced by the fish. This process is termed nitrification. Ammonia is given off by the fish and food in the aquarium. Ammonia is harmful to tropical fish. In the aquarium filter specialized bacteria consume ammonia as a food source. Their byproduct is nitrites, toxic to discus. However a second type of specialized bacteria consume nitrites as a food source. Their end product is nitrates. Nitrates are not as toxic as nitrites, but do cause problems in fish. Nitrates are removed by water changes. For more information on discus aquarium filtration and nitrification visit the discus care guide page.

Water changes are done to remove nitrates and impurities from the aquarium water. High nitrates indicate an aquarium in need of more frequent water changes. Water changes is where the reverse osmosis water comes into use.

WHAT IS REVERSE OSMOSIS?

Reverse Osmosis is a method of filtering water by pressing the water against a semi-permeable membrane that sits inside a filter housing. This membrane allows water molecules to pass through, but not others. Minerals, trace and other elements are removed producing pure raw water. This water is too pure for aquaria use without reconstituting. Marine hobbyists add salt mixes containing all the essentials. Soft water aquarists must also add trace elements and minerals back to the water to make it suitable. Pure ro water is not suitable for discus fish or angel fish.

HOW DOES THE RO FILTER WORK? Reverse Osmosis Filter Basics:

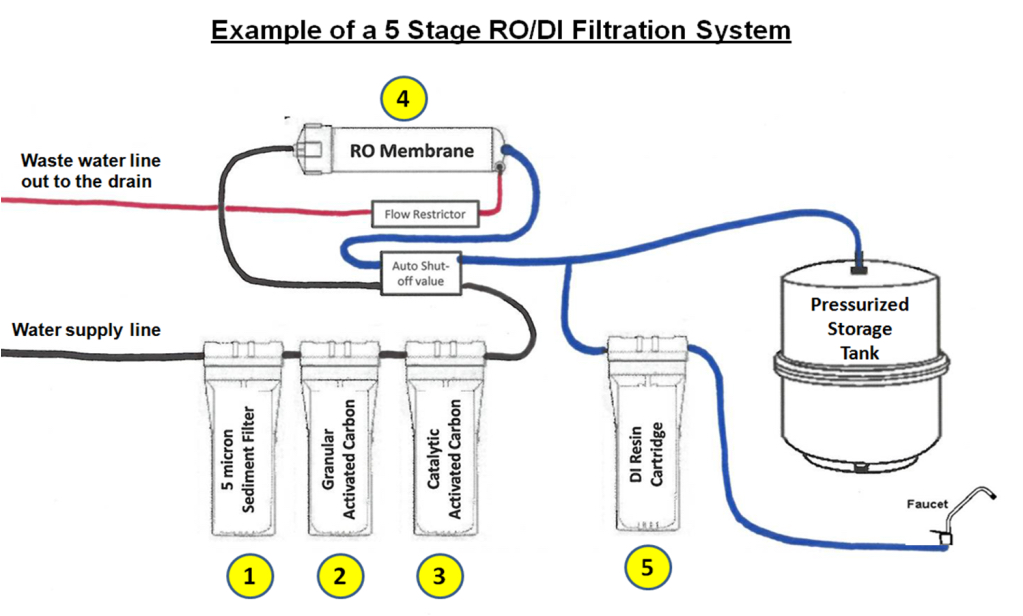

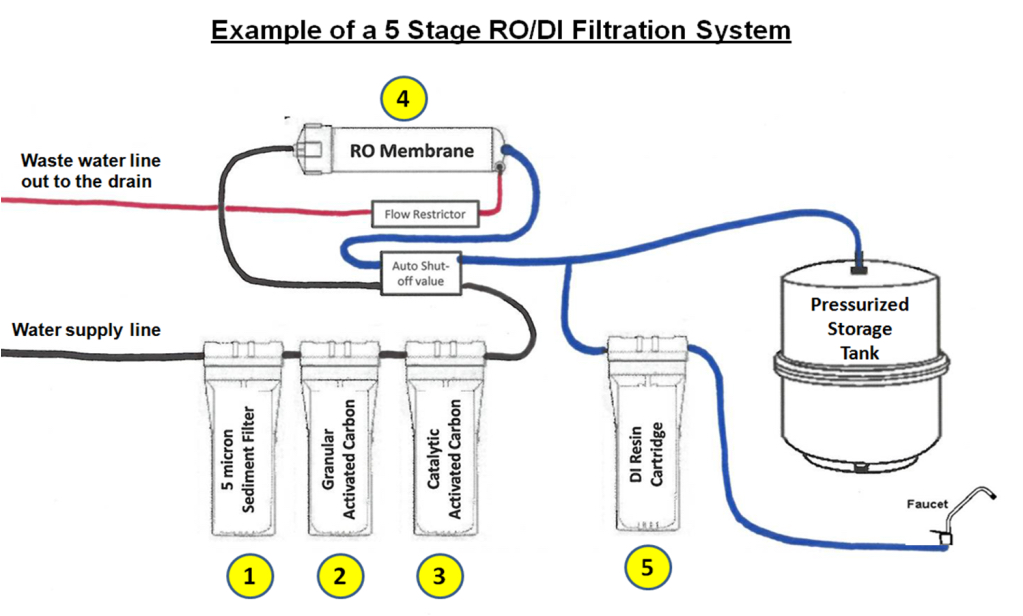

The water passes through several filters, each representing a stage.

STAGE ONE : Water enters the filter through a micron sediment prefilter. This removes small particulates, bacteria, cysts, spores and grains of sand.

STAGE TWO : The water then passes into the carbon prefilter. This removes chlorine, toxins and chemical impurities along with any pipe cleaning additives used by the water department. It is crucial that a high quality carbon block is used for this stage. The best carbon blocks available today are capable of removing chloramines, a mix of chlorine and ammonia that many municipal water suppliers now use as disinfecting agents in tap water supplies. A reverse osmosis filter is only as good as the components making up the system. Osmotic reverse osmosis filters use the highest quality components available.

STAGE THREE : Next the water passes through the membrane to complete the filtering process. There are numerous grades and types of membranes available. TFC membranes are thin film composite. They are suitable for well water or city tap water. Chlorine can damage them but a good carbon prefilter solves this. In the past distinctions were made on membrane application based upon whether it was to be used on a chlorinated tap supply or untreated well water. CTA membranes, cellulose triacetate, can handle chlorine but they are more costly, less efficient and not necessary. The vast improvement in carbon block quality will render these obsolete. The best membranes on the market are tested and certified by the NSF and approved by the FDA for drinking and food use. They feature high removal rates of silicates, phosphates, nitrates and other compounds. Contaminates removed by the filter are discarded through tubing going into a drain. The “reject” brine water used in this is the equivalent of taking a couple extra showers per week or washing the car. The reject water is not similar to turning on a faucet. It is a small stream going through 1/4″ tubing. ro is much easier to use and more economical than the other two methods of water purification which are deionization and distillation. ro water can be “polished” with di as an extra stage after the ro. for sensitive reefs requiring totally pure water. In this case the di filter is not quickly exhausted as the ro membrane has done most of the work. Pure product water (ro water) is delivered through tubing coming from the membrane. It drips out at a rate determined by the size membrane. A 50 GPD ro filter will produce close to 2 gallons per hour under ideal conditions. Performance is based upon water pressure, supply water temperature and system design. Osmotic reverse osmosis filters are designed for high efficiency. In low pressure situations a booster pump is used to increase pressure. The ro tubing coming from the membrane can be attached to a float in a sump or barrel, to the ice maker on the fridge, to a drinking water tank or any combination. An auto shutoff valve is used in this. You can tee off to as many devices as desired. However this must be configured properly. When adding floats on a drinking water system special considerations arise which must be addressed properly including the addition of a a check valve to prevent back flow from the barrel. When using a float, the auto shutoff valve must be used to prevent harmful back pressure on the membrane. Without a shutoff valve the filter must be manually turned on and off for each use by turning on the cold water supply.

ADDITIONAL STAGES: The ro filter may have a di filter on it, which is another stage. This is referred to as an rodi filter. Some have multiple carbon prefilters which represent more stages. With the new improved technology of the manufacturing processes, the best carbon blocks today remove all components of chloramines, which was unheard of just a few years ago. Osmotic ro filters use the highest grade of carbon block available today. All municipal water supply companies will be using chloramines if they are not already using them. Chloramines are chlorine and ammonia used together to disinfect the tap water. Some generic brand ro filters add unnecessary extra stages as a selling point to sound impressive and boost refill cartridge sales.

REVERSE OSMOSIS RO FILTER OPERATION

First step-The filter is attached to the tap water supply. Most ro units feature a diverter that will attach to any sink in any house. Osmotic reverse osmosis filters easily attach to any sink in the house. To operate the filter, you turn on the cold water and pull a small lever on the diverter. This sends the tap water to the unit. Simply turn off the water to stop the operation. There are several options for attaching the tap water supply to the filter. A garden hose fitting or saddle valve may be used.

Second step- Place the brine reject tubing into the sink drain. This carries impurities down the drain. If attaching the filter to a saddle valve on the cold water supply, the brine reject line can also be attached to a saddle valve on the drain line.

Third step-Place the ro product tubing into a barrel or container to hold the water. If using an auto shut off valve, attach the float at this time.

Finally, after all tubing is attached properly, turn on the cold water supply. This places the filter in operation. The efficiency is determined by the temperature of the water and the pressure of the supply water. Cold water only should be used on the filter.

Because the reverse osmosis filter is rated in output gallons per day (24 hour period) , water does not pour out of the filter. The ro water is produced in a slow, steady dripping stream. Pressure is usually not a problem on city water supplies. ro membranes require a minimum of 60 pounds of supply water pressure to operate at rated efficiency. On well systems there is a simple device to boost pressure on the filter. There are many ways to install your unit. It easily fits under the sink when used as a drinking water filter. The supply of tap water can be fed with a self piercing saddle valve or a valve that goes in line on the existing cold water shut off valve valve for the faucet. A saddle valve is also available for the drain line. The product tubing can run up or down, quite a distance to any location. When the auto shut off valve senses a demand it places the ro filter in use. When the float closes the water flow, the shut off valve turns off the filter.

IS THE AUTO SHUT OFF VALVE STANDARD EQUIPMENT ON RO FILTERS?

No. Auto shut off valves are always on complete drinking water systems. They are not a component found on most ro filters but are sold as accessories. Many hobbyist order ro filter units from mail order companies that refer them to the manufacturer for the add on options. Installing the auto shut off valve on the ro filter involves cutting all tubing and installing the valve in a precise configuration. Any time ro water is stored in a barrel, these components are necessary. For this reason, we offer a line of ro filters with these features preinstalled. For details on the barrel storage kit:

SHOULD THE MEMBRANE BE BACK FLUSHED?

Yes. When the ro filter is used strictly for drinking water a light demand is placed on the membrane. For instance a 50 GPD membrane will easily keep a standard 3 to 5 gallon drinking water storage tank topped off as water is used. However, when the ro filter is used for other applications and larger storage barrels are filled and frequently depleted of water, the membrane is placed under a heavy demand. In this case it is advisable to back flush the ro membrane on a regular basis. This simply involves opening a valve for 3 to 5 minutes to flush accumulated mineral deposits off of the membrane. Remember, water is pressed against the ro membrane and pure water passes through while solids (minerals) are eliminated by the brine reject line. With time, suspended and precipitated solids accumulate on the membrane. This reduces membrane efficiency. Back flushing removes much of this deposit. This will ensure optimum life for your membrane. Osmotic ro filters have this feature as standard equipment. Most ro filters sell this as an add on option. To add a membrane back flush valve to your existing ro filter for $15.

HOW OFTEN MUST COMPONENTS BE REPLACED?

This varies depending upon demand and water conditions. As a rule of thumb, the sediment prefilter cartridge should be replaced every 4 months. The sediment filter works from the inside to the outside. When discoloration is visible it is time to replace it. Some ro filters feature a uv resistant clear sump housing which allows cartridge condition to be checked at a glance. The carbon block prefilter should be replaced every 6 months. Keeping the sediment filter clean protects the carbon block from clogging. As filters become exhausted, system efficiency and ro water output declines. The membrane replacement schedule is variable. On a drinking water filter the average life is three years. On a system used in aquaria the time is shorter due to the higher usage. Membrane life can be prolonged by using a membrane back flush valve. This is explained in the paragraph above. If filter output sharply declines even with new prefilter cartridges, it is time for a membrane replacement. The harder the water in your area the faster a membrane is exhausted. The condition of the membrane can be tested with an electronic pen tester. As the membrane becomes exhausted, the TDS (total dissolved solids) will rise. It is normal for ro water to have some change in ph as tap water can vary in ph and changes dramatically twice a year in many areas.

CAN I UPGRADE MY EXISTING RO FILTER TO A HIGHER OUTPUT?

Yes. The 100 GPD membrane will fit your existing ro filter membrane housing. It is physically the same diameter as the smaller membrane but is much denser. You can upgrade your ro filter as easily as changing the membrane and flow restrictor fitting. The flow restrictor meters the flow to match the membrane. A 100 GPD membrane is only a few dollars more than a 50 GPD membrane. A 150 GPD membrane will fit your standard housing. For details: 150 gpd ro membrane

SHOULD A DI FILTER BE USED WITH THE RO FILTER?

The rodi filter provides the purest water possible for aquarium use. Reef and marine aquaria require pure water. For discus and soft water fish it is not necessary but some choose to use it and then reconstitute to the desired parameters. To purchase a di filter to add to any ro filter or di refill cartridge visit our ro filter sales page.

HOW SHOULD RO WATER BE USED IN AQUARIA?

RO water should be used whenever soft pure water is desired. In marine and reef aquaria, the ro water is blended with salt mixes appropriate for the intended use. This adds trace elements, salts and minerals necessary to maintain life. Using pure water eliminates the cause of many unsightly problems encountered with tap water. Impurities, including phosphates, nitrates and silicates are removed. Many of these impurities provide nourishment for undesirable bacteria, algae forms and other undesirables. For discus and other soft water fish, the ro water is reconstituted. This means adding the trace elements and minerals back into the water. For discus breeding, the water can be reconstituted using commercial products until the desired hardness is achieved. Tap water that has been purified by carbon filtration can be used to reconstitute the ro water. The filtered tap water is carefully blended with the ro until the correct hardness is achieved. This will give you softer water with a proper ph level. This method is fine for growing and maintaining discus. You can use a measuring cup to determine the ratio of tap to mix with ro. It is not necessary to blend the ro water and tap water in a barrel. When changing water, you can add the proper amount of ro water to the tank followed by the tap. If the tap is unfiltered a dechlorinating agent must be used. These contain salts and often buffers are added to them which can alter the water chemistry, possibly defeating the purpose of using ro. Use care in choosing which dechlorinating product to use. The obvious choice is to remove chlorine and harmful substances from the tap water by carbon filtration. Python type refill tubing can be plugged directly into the carbon filter and used at temps suitable for discus. Tap water filters are inexpensive and remove major impurities from the water including disinfecting agents such as chlorine. Care must be used to select one that is rated for warm water.

RO water should be stored in a food grade drum, large size ro drinking water tank or large water container approved as food grade. Food grade barrels are a little more expensive than trash cans or other containers, which may have various chemicals including mildew retardants added to them during manufacture. Garden hose is unsafe due to the chemicals used in many of them. Some may be okay but it is a risk not worth taking. Clear poly tubing is good for moving water. The storage container should have constant aeration. Heat should be provided.

On a regular basis the storage barrel should be cleaned. This should also be done to canister housings when replacing cartridges. To clean filter housings scrub well with a weak vinegar solution followed by rinsing. Tap water should not be added to the ro storage barrel. Dechlorinating products should not be added to the barrel. You do not want the nitrification process starting in the storage vessel as the water could then contain ammonia, nitrites or nitrates. When using the blend method, pump the ro into the aquarium followed by the tap. A pump with tubing (simple aquarium submersible powerhead pump) is used to deliver the water from the storage barrel to the aquarium. Never use a garden hose. Use clear poly tube. The clear tubing can easily be cleaned periodically by submersing for a few hours in a 5 gallon bucket with hydrogen peroxide. This can also be used to clean the barrel. Attach a small powerhead to the tubing to circulate the water through the tube. Drain and rinse well. In the past, 100 GPD membranes were large and bulky and did not fit standard size housings. Due largely to demand from aquarist use, manufacturers now make higher capacity membranes that easily fit standard size housings. In the past, a 100 GPD filter involved stacking two 50 GPD membranes into “piggyback” fashion. When membrane replacement time rolled around you had to obtain two membranes. The recent advances in component manufacture make ro filtration an economical solution to water purification for aquarists. With all municipal water supplies switching from chlorine to chloramines (ammonia and chlorine) as the disinfecting agent in tap water, carbon block manufacturers have designed filters to remove chloramines. I hope this has given you some insight into the area of using ro filtration in the discus fish aquarium and any aquarium application requiring soft, pure water.

Leave a Reply

You must be logged in to post a comment.